Automatic tin filling machine tin filling line for powder and solid products

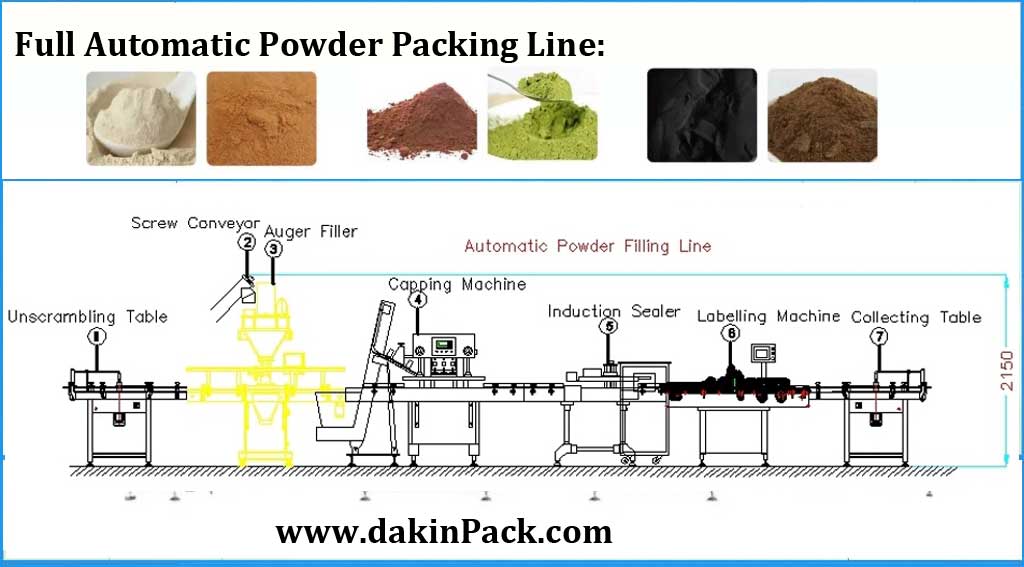

Automatic tin filling machine set up tin filling line, and jar filling line, mainly used to fill materials such as solid particles tea, coffee bean, nut or coffee powder into containers like tin, jar, and bottle.1. Automatic tin filling line and jar filling line usually consists of the following parts:

(1): Feeding system: used to transport solid materials to the filling area, generally using devices such as screw conveyors or vibrating plates.

(2): Positioning system: used to determine the precise position of the container at the filling position to ensure that there will be no offset or misalignment during the filling process.

(3): Measuring system: used to accurately measure the weight or volume of materials to be filled, and compare the measured value with the set value to control the filling volume.

(4): Filling device: Usually a mechanical arm or pneumatic device is used to transfer materials from the feeding system to the container.

(5): Conveying system: used to transport filled containers to designated locations for subsequent processing or packaging.

2. Tin filling line and jar filling line have the following advantages:

(1): The high degree of automation can greatly improve production efficiency and reduce labor costs.

(2): The filling accuracy is high, ensuring that the filling amount of each container is accurate and consistent.

(3): It can operate continuously and is suitable for large-scale production needs.

(4): It can adapt to containers of different sizes and shapes by simply adjusting the equipment parameters.

(5): Easy to operate, easy to maintain and maintain.

3. Application for Automatic tin filling machine + Heat shrink packaging machine:

Automatic tin filling machine line for solid products are widely used in food, medicine, chemical and other fields, especially in situations where a large number of filling operations are required, such as pharmaceutical factories, food processing plants, etc. These companies can use this equipment to quickly and accurately complete the filling of large quantities of materials, improve product quality and production efficiency, and reduce production costs.

The birth of each set of equipment is inseparable from the hard-working technical team behind it. The continuous development of technology promotes the improvement and progress of packaging equipment. In the past, the editor led everyone into the customer's production base. Today, we followed the customer into our dakinPack machinery and equipment manufacturer to learn about a bottled powder food filling heat shrink packaging machine.

4. Heat shrink packaging machine

The heat shrink packaging machine uses the principle that plastic film has shrinkage properties under heating to tightly wrap the product. By controlling the heating temperature and time, the film is made to adhere closely to the surface of the product to form a strong package. The heat shrink packaging machine is also equipped with a cutter system that can automatically adjust the film cutting position according to the product shape and size to achieve packaging sealing.

Heat shrink packaging machines are widely used in various industries, such as food, electronic products, medical equipment, etc. In the food industry, heat shrink packaging machines are used to wrap food such as meat, fish or vegetables to extend the shelf life and prevent the intrusion of oxygen and moisture. In the field of electronics, this device is used to protect products from the outside environment.

5. Tin filling line and jar filling line

Tin can bottle filling machine can be connected to the sleeve labeling machine to form a Tin filling line and jar filling line. The design concept of human-machine harmony is fully reflected in the production process. During the operation of the equipment and the production process, it is always in a uniquely designed protection system. Under this situation, if improper human operation creates a safety hazard, the safety system will automatically detect it and stop operating immediately. It must be restored and approved by the inspection before it can continue. The Tin can bottle filling machine and shrink packaging machine can be used within the effective folding radius range, regardless of whether the packaging is round, square or other special shapes, and the material is glass or plastic.

The picture shows the LiptonPack tin filling line customer's on-site test site and successful acceptance. LiptonPack has many such customers to cooperate with. Not only do we have high-quality equipment and high cost performance, but our services are also recognized in the industry. If there is a need, LiptonPack Machinery is trustworthy!

5. Future development trends

With the advancement of technology and changing market demands, solid product automatic can filling lines and heat shrink packaging machines will develop in the following directions in the future:

(1): Intelligentization: By introducing Internet of Things technology and big data analysis, remote monitoring and fault warning of equipment can be realized, and the operating efficiency and stability of equipment can be improved. At the same time, artificial intelligence technology is used to mine production line data, optimize the production process, and improve production efficiency.

(2): Efficiency: As market competition intensifies, production efficiency has become one of the key factors for corporate competitiveness. In the future, automatic can filling lines and heat shrink packaging machines will continue to optimize their performance, increase production speed and automation, and reduce manual intervention and error rates.

(3): Green and environmental protection: With the increasing awareness of environmental protection, the green and environmental protection performance of production equipment has received more and more attention. In the future, these equipment will use environmentally friendly materials and energy-saving technologies to reduce energy consumption and emissions and meet the requirements of sustainable development.

(4): Customization: With the diversification of consumer demands, production equipment needs to be more flexible and customizable. Enterprises can customize the functions and appearance of automatic can filling lines and heat shrink packaging machines according to the needs of different customers to meet the needs of personalized production.

(5): Modularity and scalability: In order to adapt to changing market demands and technological advancements, production equipment needs to be modular and scalable. Enterprises can flexibly add or reduce equipment modules according to the growth of production scale and demand, reducing investment costs and maintenance costs.

(6): Safety: As industrial safety standards continue to improve, the safety performance of production equipment has become increasingly important. In the future, automatic can filling lines and heat shrink packaging machines will pay more attention to safety protection design and functions to ensure the safety and health of operators.

(7): Cross-border integration: As the trend of cross-integration between various industries intensifies, the application fields of solid product automatic can filling lines and heat shrink packaging machines will be further expanded. For example, innovative application scenarios such as applications in the field of smart homes and combination with robotic technology will continue to emerge.

News from drip coffee bag packing machine factory, pyramid tea bag packing machine manufacturer, tea box wrapping machine supplier, tea bag cartoning machine exporter, multi lane stick packing machine.