Carton erector machine improves productivity for production line

Carton erector machine refers to a special carton forming machine equipment that automatically completes unpacking, forming, folding the bottom leaf, and currently completes the tape pasting of the lower part, opens the box board stacked into cardboard, folds the bottom of the box according to a certain procedure, and seals it with tape before conveying it to the packing machine, which will help to improves productivity for production line, for drip coffee bag, pyramid tea bag. It is also called carton opening machine.Product introduction:

1. High-quality imported parts:

Imported parts, electrical parts and pneumatic components are selected;

2. Exquisite high-tech international technology:

dakinPack Company has more than ten years of experience in independent research and development of unpacking machines, and has absorbed advanced technologies in unpacking machines from international peers such as Japan and Germany.

3. Unique and exquisite appearance design:

① The dominant color of this unpacking machine is beige, and it can also be configured with machine colors suitable for the corresponding production line according to customer needs;

② Lightweight, pulleys complement each other, flexible displacement, and more convenient installation and debugging.

4. Unique structural design:

① Adopt vertical cardboard storage method, and can replenish carton boards at any time without stopping, more time, more packaging;

② This carton opener structural design: complete carton suction, unpacking, forming, bottom folding, bottom sealing and other packaging processes at one time.

5. Reasonable optimization of powerful functions:

① Suitable for automatic unpacking and bottom sealing of cartons of various sizes. If you need to change the carton specifications, you can adjust it manually, and the required time is 1-2 minutes;

② This carton opener can be operated alone or in conjunction with an automated packaging line.

6. Excellent packaging performance:

① This carton opener has stable performance, high quality, strong applicability, high packaging efficiency and long service life;

② High degree of automation: automatic unpacking, automatic folding of the lower cover, automatic sealing of the lower bottom tape. The machine adopts PLC+display control, which greatly facilitates operation and is an indispensable assembly line equipment for automated large-scale production.

7. Safe and considerate protection design:

①The performance of the machine parts is precise and durable, the structural design is strict, the operation process is vibration-free, and the operation is stable;

②Equipped with a blade protection device to avoid accidental stabbing during operation, safe production, and efficient packaging.

Relying on the above advantages, the carton automatic forming and sealing machine DK-40 has been widely used in food, medicine, beverages, tobacco, daily chemicals, toys, electronics and other industries at home and abroad

As China's most professional packaging machinery R&D manufacturer, dakinPack has more than 10 years of professional design and manufacturing experience in carton openers. The product R&D center provides you with professional packaging machinery technical consultation and professional design, and tailors special packaging machinery for customers to meet the needs of different customers. dakinPack's motorized maintenance team provides you with technical support to solve carton opener problems. Excellent quality, enthusiastic service, and brand commitment will allow you to have no worries.

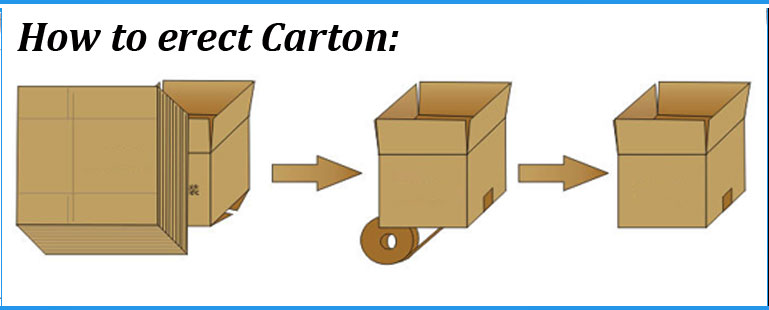

The unpacking process of carton opening machine is as follows:

Accessories introduction:

Motor: Taiwan Taibang

Blade: Japan SKD11

Human-machine interface: Taiwan Weilun

Electrical components: Japan Omron

Pneumatic components: Taiwan Xingong

PLC: Japan Panasonic

Belt: Imported from Italy

Vacuum generator: Japan SMC

Technical parameters:

Machine model: DK-40

Unpacking capacity: 10-12 boxes/minute

Temporary storage of cartons: 100pcs (1000mm)

Carton size: L: 200-450 W: 150-400 H: 100-340mm

Power used: 220V 1ф 200W

Required air pressure: 6kg/square centimeter

Air consumption: 450NL/min

Machine size: L2000×W1900×H1450mm

Machine weight: 400kg

Why do we need a carton forming machine?

Carton forming machines are essential equipment in automated mass production, mainly because they can automatically complete carton unpacking, forming, bottom folding and tape pasting, greatly improving the efficiency and automation level of packaging production.

For example, if you build a drip coffee cartoning production line or a triangle tea bag packaging production line, in order to improve the automation rate, you can add a carton forming machine at the back end of the production line.

As a manufacturer of drip coffee packaging machines and triangle tea bag packaging machines, it is our professional requirement to recommend cartoning machines to our customers, match them with carton forming machines, and provide solutions.

Carton erector machine, carton erector machine manufacturer, cardboard box erecting machine, box opening machine, case former, case erector, paper carton erecting machine, carton opening machine.