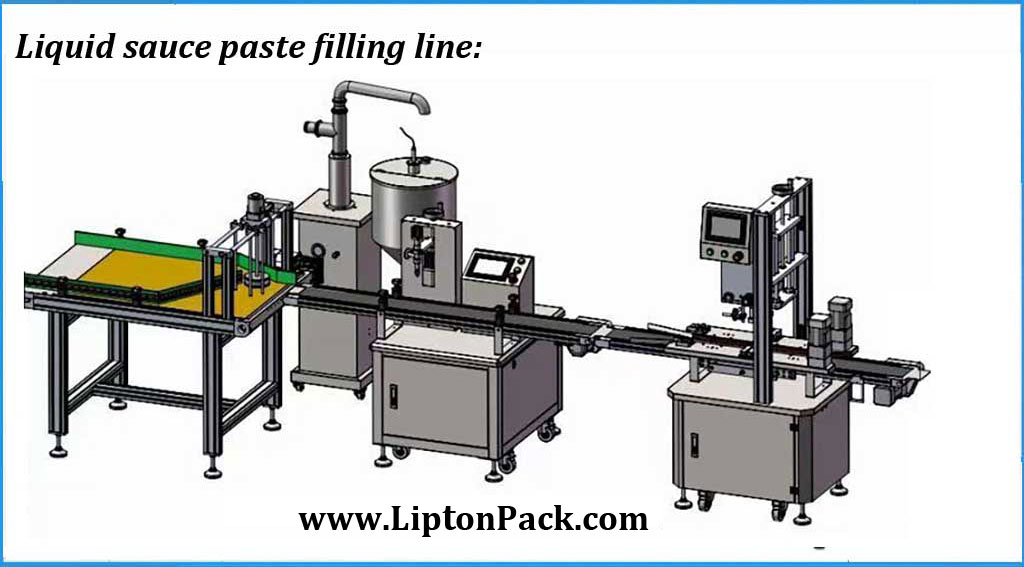

30-100g paste liquid weighing filling machine line

Features of 30-100g paste liquid weighing filling machine line:

1. The 30-100g paste weighing filling production line has automatic skinning function, automatic weight detection, and automatic diving filling.

2. The required filling weight can be set arbitrarily within the design range.

3. The barrel weighing filling line adopts a three-stage deceleration system at the end of the filling process, which automatically decelerates when approaching the quantitative value to prevent overflow and ensure accuracy.

4. The 30-100g paste weighing filling production line adopts a drip-proof filling nozzle and a drip-proof receiving tray to prevent material dripping.

30-100g paste liquid weighing filling machine line and Production Line Precautions for use:

1. Do not install in direct sunlight, especially the control instrument part, and avoid sudden temperature changes and strong mechanical vibrations;

2. When the temperature is about 20℃ and the relative humidity is about 50%, the instrument is in the best working condition;

3. It is strictly forbidden to connect the ground wire of the 30-100g paste weighing filling production line with the ground wire of other equipment;

4. The instrument grounding terminal must be reliably connected to the ground, otherwise the instrument reading may be unstable;

5. Always observe the liquid level of the oil storage tank. When the liquid level exceeds 2/3, please open the drain valve in time to drain the oil. After draining the oil, please close the drain valve.

6. The weighing tray of the barrel weighing filling line should not touch the side of the machine;

7. The weighing tray should be adjusted to a level; when filling, the oil nozzle should not touch the barrel wall.

The working principle of the 30-100g paste liquid weighing filling production line is to use the high measurement accuracy of the electronic scale to connect the electronic weight signal sensor and the weighing control instrument with a data line. During the measurement process, the pressure signal of the electronic scale is continuously transmitted to the control instrument. When the preset quantitative weight is reached, the control instrument controls the pump to stop and close the pneumatic valve.

As a highly automated packaging machine, 30-100g paste liquid weighing filling machine line are mainly used in multiple industries, including but not limited to food, pharmaceuticals, pesticides, chemicals and other fields. The following are detailed application industries and their characteristics:

1. Food industry

Application products: Paste packaging machines are widely used in the food industry for the packaging of paste products such as honey, jam, and condiments (such as sesame paste, sweet noodle sauce, ketchup, cream, etc.).

Features: It can ensure the hygiene standards and safety of food packaging, improve production efficiency, and meet the rapid packaging needs of the food industry.

2. Pharmaceutical industry

Application products: In the pharmaceutical field, paste packaging machines are often used for the packaging of ointments, creams and other medicines.

Features: The pharmaceutical industry has extremely high requirements for hygiene standards. The fully automatic paste packaging machine is made of food-grade materials, which fully meets hygiene standards and ensures the safety and sterility of medicines.

3. Pesticide industry

Application products: Paste packaging machines are also suitable for the packaging of pesticide products, such as various paste pesticides.

Features: Pesticide packaging needs to take into account the stability and safety of the product. Paste packaging machines can ensure the accurate measurement and sealed packaging of pesticide products to prevent leakage and pollution.

4. Chemical industry

Applied products: In the chemical industry, paste packaging machines are used for the packaging of chemical products such as lubricants, glues (such as glass glue, sealants, white latex, etc.).

Features: These chemical products are often viscous or fluid, and paste packaging machines can complete packaging tasks efficiently and accurately, improving production efficiency and product quality.

5. Other industries

Paste packaging machines are also used for filling and packaging of paste products such as daily chemicals (such as toothpaste, shoe polish, moisturizer, lipstick, etc.) and special industries.

In summary, paste packaging machines and paste liquid weighing filling machine line play an important role in many industries with their advantages of high degree of automation, comprehensive functions and wide application. With the advancement of science and technology and the development of industry, the application scope and performance of paste packaging machines will continue to expand and improve.